What We Do

Print Production Optimization

Paper, Board and Metal Decoration

For new and older equipment

Is your pressroom running efficiently, or are hidden costs draining your profits?

Our Print Production Optimization (PPO) uncovers and eliminates the hidden waste traditional audits miss – process and procedures that allow you to get the most out of your pressroom.

Change jobs like Formula 1 pit stops and streamline operations for faster, less interrupted printing.

From quick fixes to complete operational restructuring, PPO helps printers significantly reduce costs, maximize productivity and increase profitability – without expensive press investments or upgrades. ROI in a matter of months or even weeks.

Do you want to know where you are

really losing a lot of money?

Use our experience, built up from experts with know-how of the best printers in the world.

Most print shops track costs, output and productivity – but only days or weeks later with the post-calculation and because the KPI figures cannot show the causes, the search for causes becomes a puzzle and at some point only the deviation is recorded. This means that the most companies are not working at full strength to reduce their costs and inefficiencies.

Do your post-calculations often show worse results than your pre-calculations?

Are your salespeople saying that your production is too expensive?

Is your competition consistently offering lower prices than you?

Do your KPIs signal that something is wrong, but the root cause always seems to be different—and hard to pinpoint?

“After just one week of Print Production Optimization, Ralf had documented the main time wasters and made recommendations for action. Now that we have implemented them, we have saved so much production time that we can almost do it without an entire line.“

COO, L. Greater Europe Can Producer

Testimonial

Print Production Optimization

Print Production Optimization (PPO) is tailored specifically for print shops, packaging producers, and pressroom environments. With deep expertise in offset, digital, flexo, screen, and gravure printing, we deliver actionable insights, precise optimizations, and sustainable results.

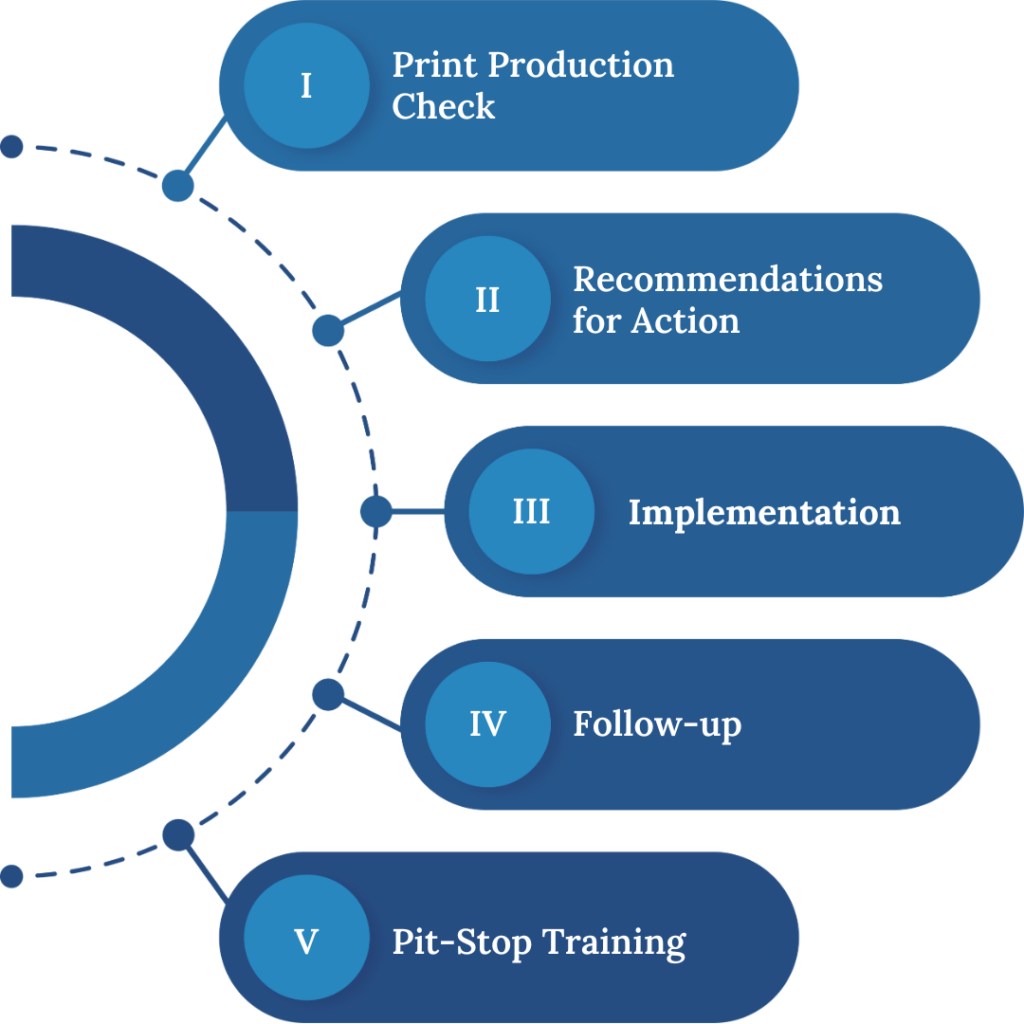

How It Works (Our Methodology)

Here’s how PPO transforms your pressroom:

- Print Production Check: We start with a structured on-site assessment to uncover inefficiencies and identify hidden improvement potential.

- Recommendations for Action: You receive a tailored roadmap with clear, actionable steps to optimize your processes.

- Implementation: We support you in putting the recommended measures into practice, ensuring real operational impact.

- Follow-Up Check / Audit: A second assessment verifies the improvements and uncovers additional potential.

- PitStop Training: Based on your specific needs, we train your team using methods inspired by Formula 1 pit crews—focusing on faster set-ups, less downtime, and higher efficiency.

Print Production Check

In other words, we review your printshop’s performance-related processes and procedures, develop optimization options, highlight weaknesses and strengths, and, if you wish, work with you to implement them.

Use Cases – When Should You Consider PPO?

Consider PPO if you’re:

When your sales department is faced by low prices from competitors

When there are increasing differences between preliminary and final costs

When you are considering new investments for capacity or technical reason

When you want to know how you stack up against the competition on print quality and quantity.

Business ROI

A medium-sized printer improved its processes, reduced makeready times and cut machine downtime with PPO, saving around 30 per cent in production time for the same jobs. This is the equivalent of a full shift and has enabled the company to postpone a major new investment for several years.

Case Studies

Streamlining Pressroom Operations

A European packaging group with several production sites had completely different quality and production figures despite similar orders and machines. Production at some sites was 40 to 60 per cent more expensive than at others.

Using Print Production Optimization, we were able to identify the causes and work with the customer to eliminate them. The cost savings from these measures are well into the millions of euros.

The customer now wants to take the next step and pit its sites against each other in a kind of competition for makeready and production times. The winner gets five days’ extra vacation, and the other sites are given the winner’s setup times as a target.

*Results from real industry implementations; company names are withheld due to NDAs.

“Ralf’s knowledge and expertise have revolutionised our press

room. We are now working in a leaner, smarter and much more cost-effective way. If you don’t know Ralf, you don’t know printing technology.“

Operations Director, European Packaging Manufacturer

Testimonial

Meet Ralf Gumbel

Ralf Gumbel is a highly experienced print industry expert and management consultant with over 30 years of executive leadership in printing technologies and production optimization. His extensive experience covers the full spectrum of printing technologies, including digital, offset, flexo, gravure, and screen printing, granting him an unmatched, comprehensive view of industry operations and challenges.

Ralf has served as CEO and senior executive at renowned global companies such as Heidelberg, Koenig & Bauer, and Manroland, where he successfully led innovation in printing press design and manufacturing. His profound technical knowledge and hands-on expertise have earned him multiple patents in printing inks, mechanical engineering, dampening solutions, and production workflow enhancements.

Beyond technical proficiency, Ralf understands that operational excellence is achieved by combining advanced technology with optimal human performance. Through his specialized consulting services—including the Print Production Optimization program and PiT-Stop Training inspired by Formula 1 racing—he helps printing companies dramatically cut waste, enhance productivity, and achieve sustainable profitability without massive capital investments.

Ralf Gumbel is an independent consultant and Partner at Brandt & Partners, an international network focused on executive search, specialized business consulting, and talent development. He leverages cross-sector insights and his extensive operational acumen to deliver tailored solutions specifically designed for print and packaging businesses worldwide.

Frequently Asked Questions

PPO is a specialized consulting framework designed exclusively for printing businesses. It uncovers hidden inefficiencies, optimizes setup processes, and reduces unnecessary downtime to drive measurable cost savings and increased productivity—without costly equipment investments.

Traditional audits typically focus only on surface-level issues and standard KPIs. PPO goes deeper by analyzing on-site operations, uncovering subtle but significant inefficiencies, and recommending actionable, sustainable solutions tailored specifically to your print operations.

Tracking productivity and costs provides only outcomes, not reasons. PPO identifies the underlying causes of inefficiencies, providing precise, practical strategies to permanently solve them rather than simply observing their effects.

No. PPO benefits both struggling and high-performing print operations by identifying opportunities for further efficiency improvements, cost reductions, and productivity enhancements that traditional methods overlook.

The Print Production Check involves a quick 1-day or detailed 5-day on-site assessment. Our experts observe workflows, setup processes, and production data, then analyze and present clear, actionable recommendations for immediate improvements.

We strictly adhere to confidentiality agreements and ensure complete data protection. Your operational data and insights are secured and used exclusively to optimize your print production performance.

Clients typically achieve significant setup time reductions, material savings, and productivity increases. ROI is often realized within three months, with annual savings regularly exceeding six figures.

The initial Print Production Check is completed in either 1 or 5 days. Comprehensive optimization (including PiT-Stop Training) typically ranges from one week to several months, depending on your specific operational needs and objectives.

Inspired by Formula 1 pit crews, PiT-Stop Training meticulously refines setup processes to reduce downtime significantly. It involves detailed analysis, practical training sessions, and implementation monitoring to achieve maximum efficiency.

Pricing varies depending on the scale and depth of your needs. Quick assessments start from €500, and comprehensive projects are priced individually based on your specific requirements. A clear proposal is provided following an initial consultation.

Simply contact us for a complimentary initial consultation. We’ll discuss your needs, explain our approach, and recommend next steps to quickly start improving your pressroom operations.

Disclaimer

The consultants (B&P Partners) featured here operate as independent service providers. Brandt & Partners assumes no responsibility or liability for the accuracy, completeness, or quality of the content displayed, nor for any actions or outcomes resulting from services provided independently by these consultants.